Process Optimization

Improve wrinkles

Traditional cotton dyeing uses low liquor ratio circular vats for the dyeing process, coupled with equipment factors. Therefore, the result is the formation of stubborn wrinkles in polyester fabric during dyeing due to fabric stacking and thermal shrinkage factors.

JINTEX can provide products that are close in nature to polyester fibers, reducing the fabric's rigidity through the concept of homogeneous miscibility. When combined with suitable processes, this can effectively improve the wrinkle problem caused during the dyeing process.

Recommend Product-JinsofEco TWM-2

Improved fastness

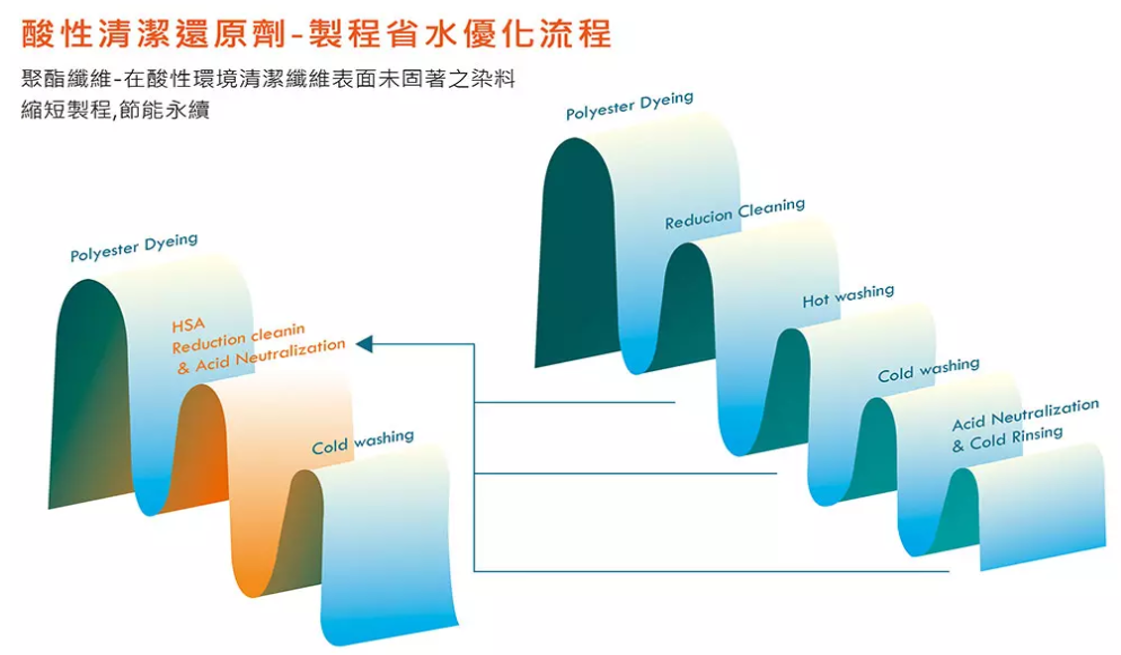

After conventional polyester dyeing, there is often an issue with surface color bleeding, which affects wash fastness. Therefore, after dyeing, a process involving alkaline reduction washing, hot water washing, cold water washing, and acid neutralization is typically required.

JINTEX provides an acid-reduction washing agent that can remove surface color bleeding under acidic conditions. This product not only exhibits efficient color removal capabilities but also can save on water washing and acid neutralization stages, effectively achieving energy-saving goals.

Furthermore, it's crucial to note that most activewear fabrics are blended with spandex. Under acidic reduction washing conditions, the risk of spandex breakage due to hydrolysis in alkaline environments is significantly reduced.

Recommend Product-Reduction HSA

Abnormal spandex yarn breakage handling

Occasionally, active-wear fabric may encounter the issue of spandex breakage during the finishing stage after dyeing. There are numerous factors contributing to this problem, including spandex quality, equipment tension, chemical factors causing spandex hydrolysis during processing, and even unavoidable dyeing re-coloration. The repetitive high-temperature processes during re-dyeing can lead to a decrease in the physical properties of spandex yarn or even breakage.

JintexEco OPP-1, which can form a protective film on the surface of fibers during the dyeing process. This effectively protects the elasticity of the yarn, reducing the occurrence of spandex breakage during dyeing and improving yield.

Recommend Product-JintexEco OPP-1

JintexEco OPP-1 Action Mechanisms

The working principle of JintexEco OPP-1:

1. Without the addition of JintexEco OPP-1, yarn subjected to high-temperature processing is easy to damage its structure, leading to a reduction in elasticity or loss of yarn weight.

2. The addition of JintexEco OPP-1 forms a protective film on the surface of the fibers, enhancing the strength of the fibers, especially spandex. Additionally, JintexEco OPP-1 incorporates a special flexible structure to prevent elasticity reduction caused by friction.

Improved dyeing uniformity

Traditional cotton dyeing using low liquor ratio circular vats for dyeing, combined with equipment factors, often results in a lower exchange rate of dye with the fabric. Additionally, when compared to long cylindrical vats, circular vats exhibit poorer fabric spreadability, leading to repetitive stacking and compression of the fabric. These factors contribute to color variation issues in different parts of the same batch of fabric after dyeing activewear fabric.

JinlevEco CR-359, which enhances the diffusion of dye between the fibers and improves dye dispersion. By utilizing JinlevEco CR-359, you can effectively enhance the dye uniformity of the fabric, ultimately improving the finished product quality of active wear garments.

Recommend Product-JinlevEco CR-359